The Lycoming IO-360 Overhaul Manual provides a comprehensive guide for inspecting, disassembling, repairing, reassembling, and testing the engine. It ensures compliance with FAA regulations, emphasizing safety protocols and manufacturer-recommended practices.

Overview of the Lycoming IO-360 Engine

The Lycoming IO-360 is a four-cylinder, fuel-injected, air-cooled aircraft engine designed for high performance and reliability. It features a horizontally opposed configuration, tuned induction, and a down exhaust system. Known for its durability, the engine is widely used in general aviation aircraft. The IO-360 series includes various models, each optimized for specific applications. Its design emphasizes efficiency, with precise fuel injection and a robust cooling system to maintain optimal operating temperatures. This engine is a popular choice for pilots and aircraft maintainers due to its proven track record and comprehensive support resources.

Importance of Following the Overhaul Manual

Adhering to the Lycoming IO-360 Overhaul Manual is critical for ensuring safety, compliance, and optimal engine performance. Properly following the manual prevents mechanical failures, adheres to FAA regulations, and maintains manufacturer specifications. It also ensures the use of correct tools and techniques, protecting the engine from damage. Compliance with the manual is essential for warranty validity and standardized maintenance practices, ultimately safeguarding both the aircraft and its occupants while ensuring reliable engine operation.

Pre-Overhaul Checks and Preparation

Consult the Lycoming IO-360 Overhaul Manual to ensure proper preparation, including gathering tools, reviewing maintenance history, and conducting preliminary inspections to identify potential issues early.

Engine Inspection and Compression Testing

Begin with a thorough visual inspection of the engine, checking for signs of wear, leaks, or damage. Perform compression testing to assess cylinder condition, ensuring readings fall within acceptable limits specified in the Lycoming IO-360 Overhaul Manual. This step helps identify potential issues early, guiding further repair decisions. Always refer to the manual for specific test procedures and acceptable ranges to maintain engine performance and safety standards.

Review of Maintenance and Overhaul History

A thorough review of the engine’s maintenance and overhaul history is essential to determine its current condition and compliance with FAA regulations. Examine previous repair records, overhaul reports, and service bulletins. Identify any recurring issues or repairs, ensuring all updates align with the Lycoming IO-360 Overhaul Manual guidelines. This step helps in verifying the engine’s airworthiness and ensures that all necessary modifications have been properly documented and implemented.

Disassembly of the IO-360 Engine

The Lycoming IO-360 Overhaul Manual outlines the detailed steps for engine disassembly, ensuring safe handling of components and adherence to manufacturer guidelines for critical parts removal.

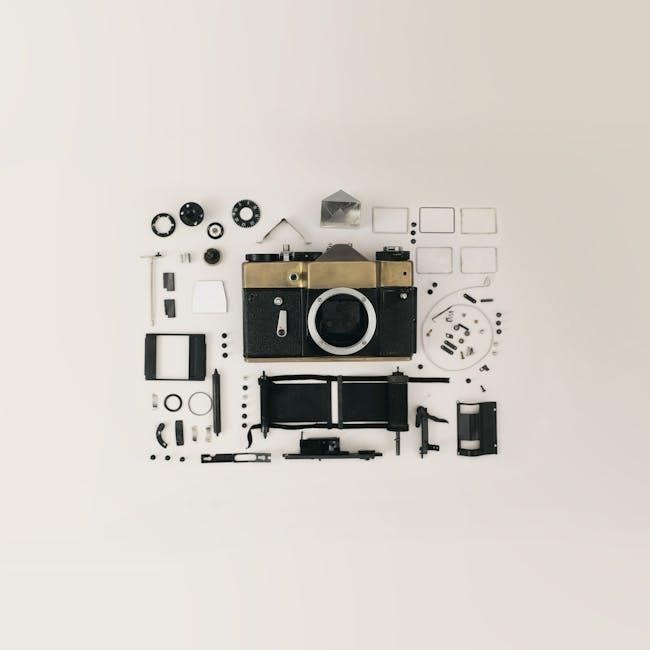

Step-by-Step Engine Disassembly Process

The Lycoming IO-360 Overhaul Manual guides technicians through a structured disassembly process. Begin by removing the cowling and disconnecting fuel and ignition systems. Next, extract the engine mounts and carefully remove the propeller. Subsequent steps involve detaching the oil sump, intake manifolds, and cylinder heads. Detailed sequences outline the removal of pistons, connecting rods, and crankshafts. Specialized tools are required for components like the camshaft and valve train. Each part is documented and stored for inspection. This methodical approach ensures safe handling and preparation for component inspection and repair.

Tools and Equipment Required for Disassembly

The Lycoming IO-360 Overhaul Manual specifies essential tools for engine disassembly. These include wrenches, socket sets, torque wrenches, and specialized pullers for components like the propeller and gears. Pliers, screwdrivers, and precision measuring tools such as micrometers and calipers are also required. Additionally, a hydraulic press may be needed for removing press-fit parts; Proper tools ensure safe and efficient disassembly, preventing damage to critical components. Always refer to the manual for specific tool recommendations to maintain compliance with FAA standards and manufacturer guidelines.

Inspection and Repair of Engine Components

The Lycoming IO-360 Overhaul Manual outlines detailed inspection and repair procedures for engine components. Dimensional checks, wear limit assessments, and non-destructive testing ensure parts meet factory specifications for safe operation.

Dimensional Inspection of Critical Parts

The Lycoming IO-360 Overhaul Manual requires precise measurement of critical components like cylinders, crankshafts, and camshafts using specialized tools such as micrometers and dial bore gauges. Each part must meet factory specifications to ensure proper engine performance and longevity. Any deviations from acceptable tolerances necessitate further analysis or repair. This step is crucial for identifying wear, damage, or manufacturing defects that could lead to premature engine failure. Adherence to these dimensional checks ensures the engine operates safely and efficiently post-overhaul.

Wear Limits and Replacement Criteria

The Lycoming IO-360 Overhaul Manual establishes specific wear limits and criteria for determining when parts require replacement. Critical components, such as cylinders, pistons, and crankshafts, must not exceed maximum allowable wear tolerances. Surface finishes, clearance measurements, and visual inspections guide these assessments. Parts exceeding specified limits or showing signs of excessive wear, scoring, or corrosion must be replaced to ensure optimal engine performance and reliability. Adhering to these criteria prevents premature engine failure and maintains compliance with factory standards, as outlined in the manual.

Non-Destructive Testing (NDT) Procedures

The Lycoming IO-360 Overhaul Manual outlines Non-Destructive Testing (NDT) procedures to identify defects without damaging components. Common methods include magnetic particle inspection for ferrous parts, dye penetrant for non-ferrous materials, and ultrasonic testing for internal flaws in crankshafts or gears. These tests help detect cracks, pits, or excessive wear that may not be visible during a standard inspection. Adhering to these procedures ensures the engine’s airworthiness and longevity, as outlined in the manual and compliant with FAA regulations and manufacturer guidelines.

Reassembly and Testing

The Lycoming IO-360 Overhaul Manual guides the reassembly process, ensuring proper torque specifications and bolt sequencing. Post-reassembly, fuel system and ignition testing are conducted, followed by an engine test run to verify performance and compliance with FAA standards.

Torque Specifications and Bolt Tightening Sequence

Adhering to the Lycoming IO-360 Overhaul Manual is critical for proper engine reassembly. Torque specifications and bolt tightening sequences must be followed precisely to ensure structural integrity and prevent damage. Improper torquing can lead to engine failure or unsafe operation. The manual provides detailed torque values for specific bolts and fasteners, along with the recommended sequence to avoid uneven stress distribution. Always consult the manual for exact specifications and use calibrated tools to verify torque accuracy. Failure to comply with these instructions may result in catastrophic engine failure during operation. Proper training and experience are essential for accurate execution.

Fuel System and Ignition System Testing

After reassembly, the fuel system and ignition system must be thoroughly tested to ensure proper function. The Lycoming IO-360 Overhaul Manual outlines specific procedures for fuel flow checks, pressure testing, and ignition timing verification. These tests ensure fuel injection and ignition systems operate within manufacturer specifications. Proper testing prevents issues like uneven fuel distribution or misfires, which can lead to engine malfunction. Always use specialized tools and follow manual guidelines to ensure accurate results. Improper testing can result in reduced performance or engine failure, emphasizing the need for precise adherence to procedures. Consult the manual for detailed instructions and safety precautions.

Engine Test Run and Performance Verification

The final step in the overhaul process involves a thorough engine test run to verify performance. The Lycoming IO-360 Overhaul Manual specifies procedures for testing engine operation under various conditions, including idle, cruise, and full power settings. This ensures proper fuel flow, ignition timing, and power output. Performance metrics such as RPM, manifold pressure, and fuel consumption are checked to confirm they meet factory specifications. Any deviations may indicate issues requiring adjustment or further inspection. Proper documentation of test results is essential for compliance and future maintenance reference. Always follow manual guidelines to ensure accurate and reliable outcomes.

Post-Overhaul Procedures

Post-overhaul procedures ensure the engine operates efficiently. This includes documentation of test results, adherence to FAA regulations, and implementing a proper break-in process. Follow the manual for oil changes, filter inspections, and performance monitoring to guarantee long-term reliability and compliance with safety standards.

Break-In Procedures for the Overhauled Engine

After overhaul, the Lycoming IO-360 engine requires a structured break-in process. Begin with fresh oil and a new filter. Conduct a series of ground runs at varying power settings to ensure proper ring seating and bearing wear-in. Monitor oil pressure, temperature, and fuel flow. Avoid extreme power fluctuations during the initial hours. Gradually increase power over several flights, adhering to the manual’s guidelines. Regular inspections during this period are critical to identify and address any potential issues early. Proper break-in ensures optimal engine performance and longevity.

Documentation and Compliance with FAA Regulations

Proper documentation is essential for compliance with FAA regulations after overhauling the Lycoming IO-360 engine. Maintain detailed records of all procedures, including inspections, repairs, and parts replacements. Ensure all work aligns with the approved overhaul manual and applicable service bulletins. Log entries must include dates, technician signatures, and compliance statements. Adhere to FAR 21.50 and FAR 43.13 requirements. Retain records for future inspections and audits. Compliance ensures airworthiness and avoids legal or operational issues. Always refer to the latest manual updates provided by Lycoming.

Troubleshooting Common Issues

Identify and address common issues like engine performance loss, fuel leaks, or ignition malfunctions. Refer to the Lycoming IO-360 manual for diagnostic procedures and solutions.

Diagnosing and Resolving Post-Overhaul Problems

Post-overhaul issues may include engine performance loss, fuel leaks, or ignition malfunctions. Consult the Lycoming IO-360 manual for troubleshooting steps. Perform thorough system checks, verify torque specifications, and ensure proper fuel flow. Address any anomalies promptly to prevent further damage. Follow Lycoming’s guidelines for resolving issues, and conduct test runs to confirm repairs. Document all findings and corrective actions for compliance and future reference. Always adhere to safety protocols when diagnosing and resolving problems.

Safety Considerations

Handling hazardous materials and tools requires strict adherence to safety protocols. Always wear Personal Protective Equipment (PPE) and consult safety advisories to minimize risks during overhaul procedures.

Handling of Hazardous Materials and Tools

Hazardous materials such as fuels, lubricants, and cleaning agents require proper handling to prevent personal injury and environmental contamination. Always follow manufacturer guidelines for storage, disposal, and safety advisories. Use appropriate Personal Protective Equipment (PPE) when working with chemicals or power tools. Ensure proper ventilation in the workspace to avoid inhalation hazards. Keep fire extinguishers nearby when handling flammable materials. Tools and equipment must be used as intended to avoid accidents. Adhere to all safety protocols outlined in the Lycoming IO-360 Overhaul Manual.

Personal Protective Equipment (PPE) Requirements

When working on the Lycoming IO-360 engine, it is essential to use appropriate Personal Protective Equipment (PPE) to ensure safety. This includes safety glasses to protect against flying debris, heat-resistant gloves for handling hot components, and a face mask when dealing with hazardous materials. Steel-toe boots and high-visibility clothing are also recommended to prevent injuries in the workspace. Always adhere to the safety guidelines outlined in the overhaul manual to minimize risks and ensure a safe working environment.